Laminated Glass Metal Mesh – Perfect Combination of Safety & Art

Laminated glass has long been prized for its safety features, but it lacked some artistry. However, the introduction of laminated glass art mesh has revolutionized this concept. It perfectly integrates artistic mesh patterns into the laminated glass structure, which not only retains the safety properties of laminated glass, but also greatly enhances its aesthetic and artistic flavor. This unique glass variant opens up a world of infinite possibilities for architects, designers and creative enthusiasts. It turns out that safety can be so attractive, allowing design not to be limited to materials and ideas to be more distinctive.

What Is Laminated Glass Metal Mesh?

Metal Mesh laminated glass, also known as shatterproof glass, is a special glass formed by heating ordinary flat glass to a red-heat softening state, pressing in multiple pieces of intermediate film or wire pattern into a semi-liquid glass belt by calendering production process. Its strength is higher than that of ordinary glass. When the glass is subjected to impact or high temperature, the glass rupture and will not be scattered, to prevent broken fragments of corners from flying out the injury to people, such as the spread of fire when the glass is subjected to heat explosion, it can still maintain a fixed state and play a role in isolating the fire.

Type

- Varieties: Embossed wired patterned glass, polished wire glass, colored wired glass, etc.

- Shapes: Flat laminated glass, waveform laminated glass, grooved laminated glass, etc.

Features

- Decorativeness: Laminated glass metal mesh can do a lot of patterns and also support pattern customization

- Safety: Its impact strength is 5–10 times that of ordinary glass.

- Fire Retardancy:

- It can withstand the temperature difference of 300 °C, and can withstand the temperature difference is 3 times that of ordinary glass.

- Wire or net can also support debris, which can maintain integrity to a considerable extent and prevent the flow of air and the diffusion of smoke, which has a good effect on the spread of fire.

Specification

- Thickness: 6–16 mm (exclude the wire mesh thickness)

- Size: generally not less than 600 mm × 400 mm, not bigger than 2,000 mm × 1,200 mm

(Note: When designing and purchasing, determine the size in advance.)

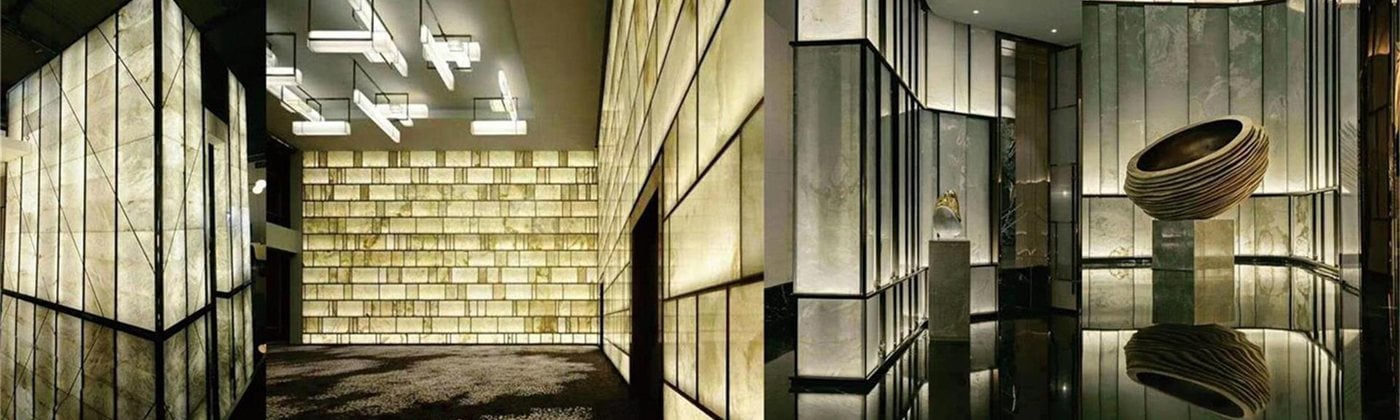

Applications & Cases of Laminated Glass Metal Mesh

Elevator interior decoration

Installation Process of Laminated Glass Metal Mesh

- Glass selection & cutting

- Categorize by specification

- Wipe clean before installation

- Scrape bottom putty

- Mosaic glass

- Scrape putty and clean edges

Precautions of Laminated Glass Metal Mesh

- Anti-Rust

- The design should pay attention to the installation area, which needs to be easy and fast to remove rainwater and prevent rusting.

- The surface of the wire mesh of wire glass is specially treated, and it is generally not easy to rust. However, the cut part is in a state of no treatment, so sometimes it will rust when it meets water.

- Transportation

- Pay attention to rain and humidity and store in a dry room.

- The glass shall not be flat or oblique, the length direction should be the same as the vehicle transport direction.

- After being transported to the construction site, if it is not needed for the time being, it also needs to be erected and placed on the A-shaped shelf.

- Installation

- The use of a four-sided frame, glass, and frame should be filled with high-quality sealing materials. It is recommended to use silicone rubber or poly-sulfide rubber sealing materials.

- When installing large area patterned glass, it should be carefully cut in accordance with the design pattern. The patchwork must be consistent to avoid dislocation, loosening, and skew.